Fire Suppression

Under certain adverse conditions, materials being laser processed have the potential to ignite and continue to burn which can cause damage to the laser cutting, engraving, and marking equipment along with surrounding property. This can create potential safety hazards for nearby personnel. The primary method for preventing this situation is constant operator supervision of the laser system when in use. As a backup, ULS developed a fire suppression option (available on ULTRA laser systems) that can help mitigate the potential for damage to the laser system and its surroundings. The fire suppression module will deploy fire suppressant into the laser material processing area if self-sustained combustion is detected. This optional backup system for fire safety has the following benefits:

- Improved Operational Safety

Provides a redundant backup to operator supervision. - Increased Reliability

Reduces or prevents damage to assets. - Improved Return on Investment

Prevents costly downtime due to damage caused by fires.

How the Fire Suppression Module Works

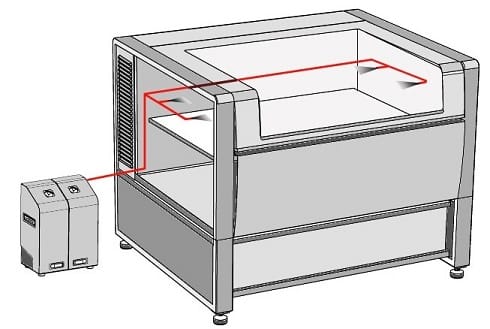

In the event sustained combustion develops in the laser system, there are two sets of redundant thermal switches located strategically in the laser system material processing chamber which will react to elevated temperatures. The first set will trigger at a certain temperature to stop laser processing and activate an audible alarm alerting the operator to address the situation. If the operator is unable to react in time, a second set of thermal switches is set to trigger at a slightly higher temperature than the first set. This will activate valves that release suppressant into the processing area to extinguish flames. The suppressant used is designed to evaporate after deployment without leaving a residue to be cleaned up. This suppressant it environmentally safe and approved for use worldwide.

Improved Operational Safety

The first line of defense against the potential of sustained combustion during laser processing is an attentive operator who is monitoring the laser processing at all times. However, as a backup, a fire suppression system can reduce or eliminate damage to expensive assets and surrounding property, thereby reducing risk and improving overall safety. This redundancy can be especially useful when processing materials that are prone to combustion or when operational errors occur: laser processing settings are not properly configured, gas assist is not properly set up, or final focus of the laser is not properly set.

Increased Reliability

Overall reliability of a laser system is improved with the addition of the fire suppression module. As a backup, the fire suppression module can prevent sustained combustion from escalating and causing damage to the laser system and surrounding property resulting in costly down time for repairs and lost productivity. As an additional safeguard, sensors monitor the levels of fire suppressant in the unit and communicate with the laser system. The sensors prevent laser processing and warn the operator if a tank is empty and needs to be replaced. A backup tank is also built into each fire suppression unit allowing the operator to switch to a second tank in the event that the primary tank is deployed. In this way, laser material processing can continue while a replacement tank is acquired.

Improved Return on Investment

ULS laser cutting, engraving, and marking machines are designed to contain sustained combustion for extended periods of time using robust enclosure materials and laminated safety glass viewing ports, but if left unchecked long enough, damage can extend to surrounding property causing even costlier repairs and delays. These repairs and delays can cause extended downtime and reduced productivity in addition to posing a safety hazard. The fire suppression unit can help prevent these costly interruptions to productivity thereby helping to maximize return on investment