PLS6.75

Platform Overview

The PLS6.75 is a free-standing platform with a material processing envelope of 32" x 18" x 8.5" or 4,896 in³ (813 x 457 x 216 mm or 80,253 cm³). The single laser platform supports either one 10.6µm CO2 laser (10 to 75 watts) or one 9.3µm CO2 laser (30, 50, or 75 watts).

Platform Specifications

| PLS6.75 | |

| Laser Material Processing Area (W x H) | 32 x 18 in (813 x 457 mm) |

| Maximum Part Size (W x H x D) | 37 x 23 x 8.5 in (940 x 584 x 216 mm) |

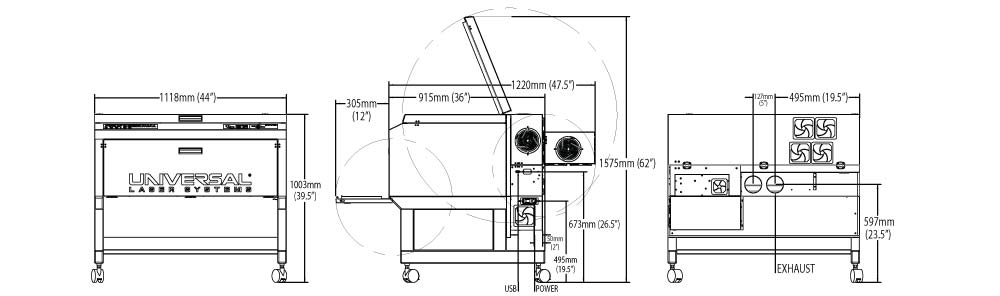

| Overall Dimension (W x H x D) | 44 x 39 x 36 in (1118 x 991 x 914 mm) |

| Rotary Capacity | Max Diameter 8 in (203 mm) |

| Motorized Z Axis Lifting Capacity | 40 lbs (18 kg) |

| Available Focus Lenses | 2.0 in (51 mm) HPDFO™ (High Power Density Focusing Optics) |

| Laser Platform Interface Panel | Keypad and LCD display show current file name, laser power, engraving speed, PPI and run time. |

| Computer Requirements | Requires dedicated PC with Windows® 7/8/10 32/64 bit and one available USB port (2.0 or higher) |

| Optics Protection | Integrated with included Gas Assist |

| Cabinet Style | Free-Standing |

| Laser Options | 10, 30, 40, 50, 60 and 75 watts |

| Weight | 325 lbs (147 kg) |

| Power Requirements | 110V/10A 220V-240V/5A |

| Exhaust Requirements | Two 4 in (102 mm) ports 500 CFM @ 6 in static pressure (850 m3/hr at 1.5 kPa) |