Processing 3M® Microcellular Polyurethane Foam Using DLMP®

3M® Microcellular Polyurethane Foam products consist of a thermoset, microcellular PU foam with or without an adhesive backing. These products exhibit good cushioning, sealing, and vibration control due to very low compression set properties. However, the open cell structure allows gas and vapors to pass through the material. When lined with 3M adhesives, this product provides high initial tack and excellent shear strength over a wide temperature range.

These foams were designed for high performance gasketing and sealing applications but also find application in automotive, aerospace, electronic, and medical industries for the purposes of sound dampening and vibration control.

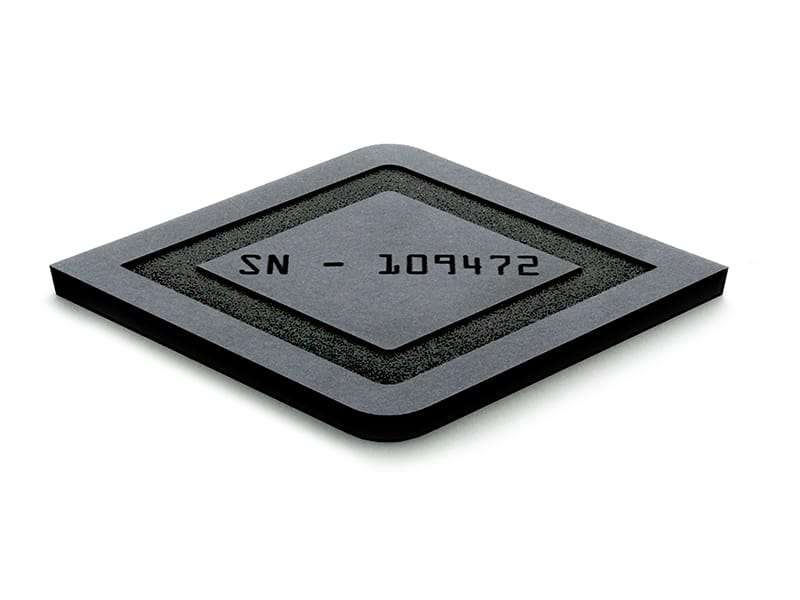

3M Polyurethane Foam is produced in 15 lb/ft3 (240 kg/m3) and 20 lb/ft3 (320 kg/m3) densities and in thicknesses from 0.0625” (1.59 mm) to 0.5” (12.7 mm). It is available without adhesive or with a variety of adhesive thicknesses, carriers, and liners. All 3M PU foams are black in color.

3M® Polyurethane Foam and DLMP® Technology

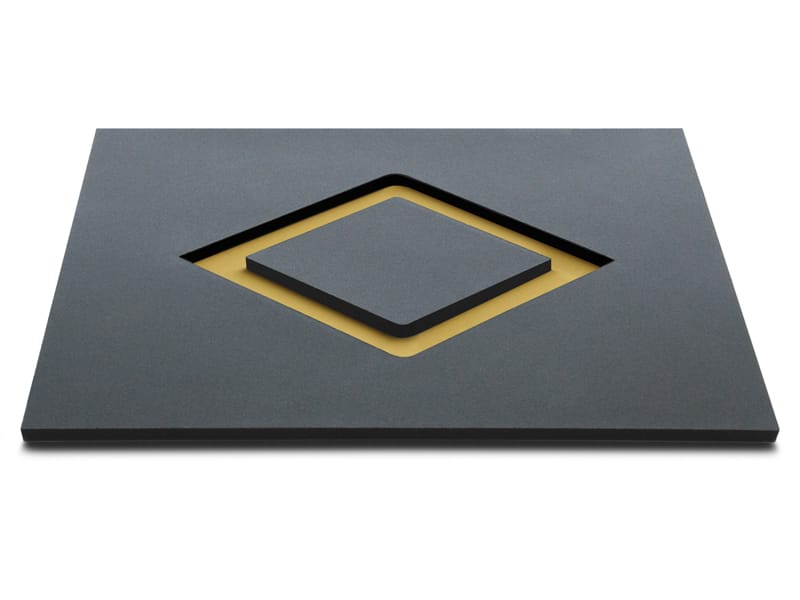

A relatively low density and thermoset chemistry are the key factors that makes 3M Polyurethane Foam easy to process with DLMP (Digital Laser Material Processing) technology. How this property influences the results of DLMP is discussed in detail in the following sections. The most useful effect of laser energy with 3M Polyurethane Foam is material ablation. In the case of 3M Polyurethane Foam, the processes of laser cutting and laser engraving apply. Each of these processes are discussed in their respective section below.

For more information see our Laser Material Processing Whitepaper.

Ablation of Material

Polyurethane is an excellent absorber of CO2 laser energy (wavelength=10.6 μm). When polyurethane absorbs laser energy, it rapidly converts optical energy into molecular vibrations (heat). Because this type of polyurethane is a thermoset, sufficient heat leads to rapid chemical decomposition. Material directly in the laser path is cleanly ablated away into vapor and fine particles.

For these reasons, CO2 lasers are commonly employed for laser ablation of polyurethane foam. The material just outside of the laser's spot or path will conduct some heat but not enough for complete and thorough ablation. This area of thermal affect is often referred to as the heat affected zone or HAZ. In the case of 3M Polyurethane Foam, virtually no HAZ is created because the low density foam structure does not require heavy heat loads to cut or engrave. Additionally, the polymer is a thermoset, so it can withstand heat without melting.

Combined Processes

Environmental, Health and Safety Considerations

Laser material interactions almost always create gaseous effluent and/or particulate. Because this product is based on a thermoset polymer, the material will chemically degrade primarily into methyl carbamate, as well as other gases, rather than melt or boil. Gaseous phase effluent is generated as well and most made up of carbon monoxide. These gases and particulate should be routed to an exterior environment in accordance with government regulations. Alternatively, the effluent can be treated with a filtration system first and then routed to an exterior environment. Some materials have a propensity to generate flammable byproducts during laser processing. Therefore, laser processing should always be supervised.