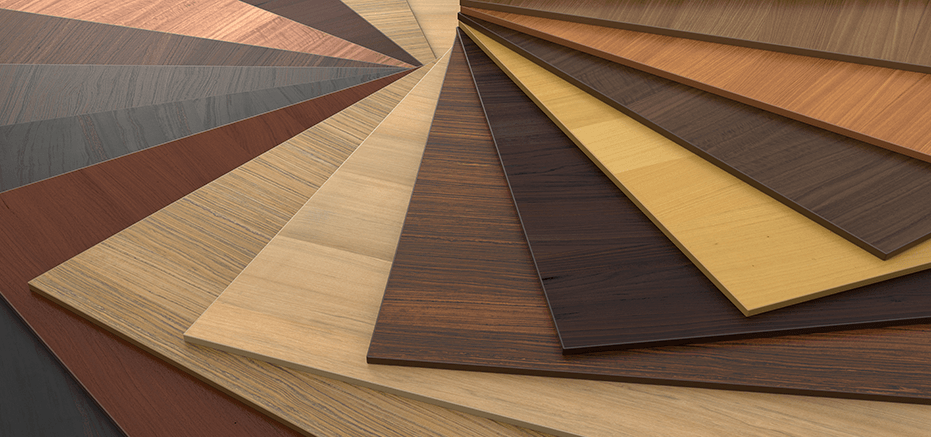

Natural (Organic)

Naturally occurring organic materials like wood and leather are derived from plants or animals. Wood is a versatile material that is very amenable to laser processing. Wood comes in many varieties, from soft woods like balsa and pine, to hard wood like cherry and maple. The softer woods are less dense and easier to laser cut than harder woods. The hard woods tend to have finer grain structures and are more suitable to laser engraving. Leather is a natural material created by tanning animal hides. The tanning process makes the leather more supple and durable. All natural organic materials can be laser cut, engraved, and marked. Visit our Materials Suppliers List for natural organic material vendors.

Types of Natural Organic Materials

- Medium Woods

- Alder

- Birch

- Soft Woods

- Balsa

- Bass Wood

- Cork Board

- Pine

- Very Hard Woods

- Ironwood

- Teak

Types of Laser Processes

Lasers are playing an ever expanding role in material processing, from new product development to high volume manufacturing. For all laser processes, the energy of a laser beam interacts with a material to transform it in some way. Each transformation (or laser process) is controlled by precisely regulating the wavelength, power, duty cycle and repetition rate of the laser beam. These laser processes include the following:All materials have unique characteristics that dictate how the laser beam interacts and consequently modifies the material. The most common processes for natural organic materials are the following:

Laser Cutting of Natural Organic Materials

The energy of a CO2 laser beam is easily absorbed by most natural organic materials. The laser beam heats the material that is directly in its path, causing it to rapidly heat up and vaporize. If the laser power is sufficiently high, the laser beam will cut completely through the material. Natural organic materials vaporize quickly when cut with a laser, resulting in smooth and straight edges with minimal discoloration.

Laser Engraving of Natural Organic Materials

The power of the laser beam can also be limited so that it removes material (engraves) to a specified depth. The laser engraving process can be used to create intricate patterns and designs in the surface of natural organic materials. Laser engraving can also be used to convey information.

Laser Marking of Natural Organic Materials

If laser power is sufficiently low, the surface of the natural organic material will be darkened but no material will be removed. This process is termed laser marking. Laser marking can be used to create designs or to convey information such a serial number or the manufacturer’s logo.

General Natural Organic Materials Laser System Considerations

Platform Size – Must be large enough to hold the largest pieces of natural organic material that will be laser processed or be equipped with Class 4 capability for processing larger pieces.

Wavelength – The 10.6 micron wavelength is absorbed well by all organic materials and is the best choice for laser cutting, engraving, and marking.

Laser Power – Must be selected based on the processes that will be performed. 25 to 150 Watts (CO2 laser) is best for natural organic laser cutting, engraving, and marking.

Lens – A 2.0 lens is the best general process lens for laser processing natural organic materials.

Cutting Table – Supports sheets of natural organic materials for laser cutting.

Exhaust – Must have sufficient flow to remove the gasses and particles that are generated by the natural organic materials laser engraving, cutting, and marking equipment.

Air Assist – Provides a jet of air near the focal point of the laser to help remove gasses and particles that are generated during natural organic material laser engraving, cutting, and marking.

Environmental, Health and Safety Considerations for Natural Organic Laser Material Processing

Laser-material interactions almost always create gaseous effluent and/or particles. The effluent and particles from natural organic laser material processing should be routed to an exterior environment. Alternatively the exhaust may be treated with a filtration system first and then routed to an exterior environment. Combustion is inherent to laser processing and may produce flames. Therefore laser material processing should always be supervised.