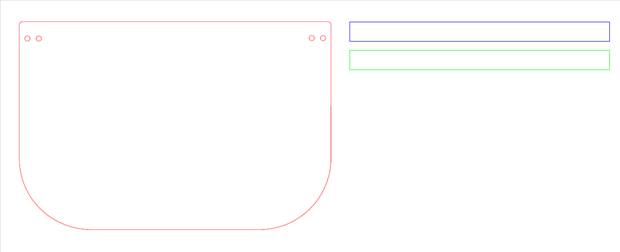

The fabrication of all parts for a face shield requires just one process - laser cutting. Laser marking for part number, logo, website or other purpose is optional and can be done directly onto the shield material.

- Plastic sheet cutting - Laser cutting the plastic sheet can be accomplished by any Universal Laser System with a CO2 laser. Time will vary with machine and laser power but is typically less than a minute. Polycarbonate is superior for impact resistance, but these shields are for splash protection so most shields of this type are constructed of lower cost and faster processing polyester film (PET/PETG). Keep the factory masking on the material or add masking before cutting to keep the material clean.

- Foam and adhesive cutting - Foam and adhesive can be cut separately or the adhesive can be added to the foam before cutting.

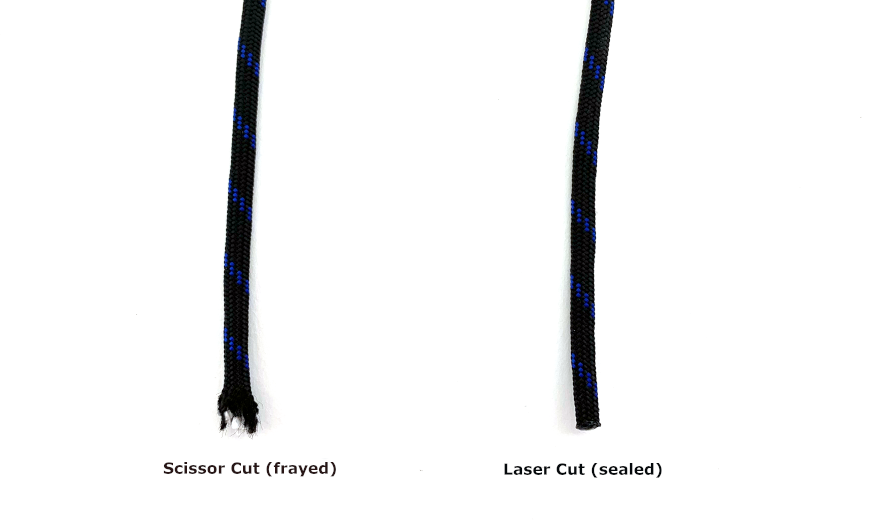

- Paracord cutting - Laser cutting is highly recommended for Paracord. Paracord consists of a woven tubular nylon sheath surrounding dozens of individual nylon filaments and strands. When mechanically cut it frays. With laser cutting, the ends are automatically heat sealed so there is no fraying.

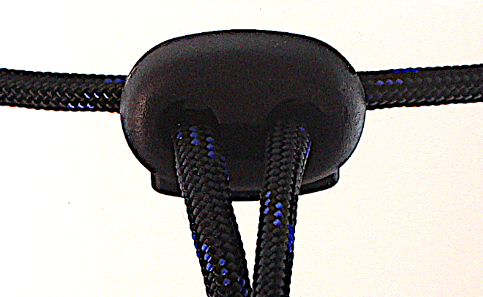

Assembly consists of attaching the foam strip to the shield with adhesive, sliding the cord lock over the cord and tying the cord to the left and right side of the shield.