MultiWave Hybrid™ Technology

MultiWave Hybrid™ technology is a patented feature that allows any combination of laser wavelengths to be focused to the same focal point within the same focal plane and used either simultaneously or sequentially. Currently, 10.6 µm, 9.3 µm and 1.06 µm laser wavelengths are available on MultiWave Hybrid systems affording the following benefits:

- Broad Range of Material Compatibility

The ability to choose from multiple laser wavelengths greatly expands the range of compatible materials. - Ease of Use

The ULS Intelligent Materials Database automatically provides the optimized laser settings for MultiWave Hybrid processes. - Maximum Return on Investment

MultiWave Hybrid platforms are capable of performing the same function as multiple single-wavelength laser systems.

How MultiWave Hybrid Technology Works

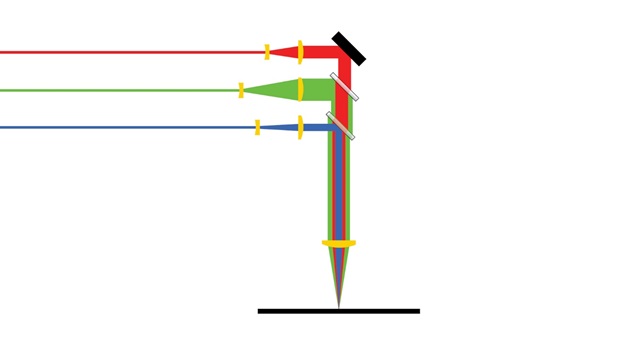

MultiWave Hybrid technology uses specially designed optics that are compatible with all three laser wavelengths offered by ULS (10.6 µm, 9.3 µm, and 1.06 µm). These proprietary optics focus combinations of these wavelengths to the same focal point within the same focal plane permitting all three lasers to be used either simultaneously or sequentially.

Each component of the hybrid laser beam, including peak power, average power, power density, pulse rate and pulse duration of each component laser beam can be individually controlled to allow optimum laser processing flexibility.

Schematic representation of three laser wavelengths being combined

to form a beam with the same focal point at the surface of a material

Broad Range of Material Compatibility

While each material behaves differently, 10.6 µm wavelength CO2 lasers are often the best choice for organic materials, including plastic, rubber, and wood. The 9.3 µm wavelength of CO2 lasers are a better candidate for specialty materials such as PET and Kapton®. The 1.06 µm wavelength fiber lasers are most compatible with inorganic materials such as Copper and Steel.

The examples below illustrate a small set of materials that have been processed with individual laser sources of a single wavelength.More complex laminates and composite materials are composed of a variety of component materials. This makes them ideal candidates for MultiWave Hybrid processing since each component material may interact preferentially to one wavelength over another. The examples below show the results of MultiWave Hybrid processing on a small set of materials along with the results of using only a single wavelength. CFRP processed with 10.6 µm (left), 1.06 µm (center), and MultiWave Hybrid (right). The top row shows the ½” (12 mm) diameter cuts in full scale. The bottom are the same cuts under magnification. The MultiWave Hybrid process results in the smallest Heat Affected Zone (HAZ) and fewest frayed fibers.

Microscopy images (300x) of the processed edge resulting from MultiWave Hybrid processing (left), 9.3 micron processing (center), and 10.6 micron processing (right). MultiWave Hybrid resulted in the smallest HAZ and removal of the metallic fillers.

Ease of Use

To process a material, the user simply selects the material from the Intelligent Materials Database and, if cutting, enters the material thickness. The database then automatically calculates the optimal settings for each laser process.

The Intelligent Materials Database is developed and maintained by the Advanced Materials Processing Center (AMPC) at ULS. This group of engineers optimizes laser settings for processing an ever increasing number of materials using the three laser wavelengths described in the previous section. Once tested, these materials become available to customers with each new software update.

Maximum Return on Investment

MultiWave Hybrid technology permits multiple laser sources of different wavelengths to be used on the same system. This means that a single MultiWave Hybrid system can take the place of up to three single-laser systems. Moreover, ULS Laser sources can be Rapidly Reconfigured to quickly set the system up with the ideal combination of laser power and wavelength for any application. Some examples include:

- Laser cutting carbon fiber reinforced plastic: 1 x 75 Watt 10.6 µm laser and 1 x 50 Watt 1.06 µm laser

- Laser cutting multi-material laminate: 1 x 50 Watt 10.6 µm laser and 1 x 50 Watt 1.06 µm laser

- Rapid prototyping for flexible circuit fabrication: 1 x 75 Watt 10.6 µm laser 1 x 30 Watt 9.3 µm laser and 1 x 50 Watt 1.06 µm laser

- Selective laser ablation of thin film materials: 1 x 50 Watt 10.6 µm laser and 1 x 50 Watt 1.06 µm laser

- Laser cutting silicon wafer: 1 x 75 Watt 10.6 µm laser and 1 x 50 Watt 1.06 µm laser

,_1.06_um_(center),_and_multiwave_hybrid_(right).jpg)

_of_the_processed_edge_resulting_from_multiwave_hybrid_processing_(left),_9.3_micron_processing_(center),_and_10.6_micron_processing_(right).jpg)